Researchers have long been experimenting with dilute combustion engines that increase efficiency and reduce combustion emissions. But it is difficult to ignite them

There are about one billion cars on the world's roads today, and almost all of them are powered by internal combustion. This 150-year-old technology is at the heart of most forms of transportation, from airplanes to trains or ships. The importance of the engine is such that different generations of intelligent people have devoted a lot of life and capital to improving it. However, the internal combustion engine has a major drawback: it kills our planet

Most combustion engines burn fossil fuels, producing greenhouse gases such as carbon dioxide and nitrous oxide. In the United States, this sector is responsible for almost one-third of greenhouse gas emissions, despite numerous policies designed to limit the environmental impact of transportation. The internal combustion engine is basically a dirty technology; But there are many ways to clean it. These motors are lit with a spark, in other words, with the help of a spark plug.

David Howell is director of the US Department of Energy's Office of Vehicle Technology and has been thinking about how to build better engines for a long time. This year, about $ 70 million (about a quarter of its annual budget) will be spent on combustion and fuel research and development. "We're seeing a lot of progress in battery-powered electric vehicles, but internal combustion engines have remained the same for a long time," says Howell.

In combustion engines, there is a strong correlation between efficiency and emissions. A more efficient engine uses less fuel to do the same amount of work, and less fuel means less greenhouse gas emissions. For years, the Office of Vehicle Technology has focused on replacing conventional gasoline with environmentally friendly biofuels. "The internal combustion engine can use a variety of fuels, and some of them are somewhat renewable," says Howell.

But the elimination of gasoline does not happen so quickly. New biofuels must not only perform well on gasoline, they must also be cheap. In addition, a lot of work has been done on gasoline. "Gasoline has been around for a century, and a lot of optimizations have been made about its combustion properties," says Howell. So until new fuels are ready for public use, researchers are looking for ways to make better use of old, conventional gasoline in current engines.

A typical car engine combines air and gas in a combustion chamber and then ignites the mixture using a spark plug. The technology, which is a century old, is located in the combustion chamber and is installed near the top of the engine at the cylinder head. As the piston moves to the top of the chamber, it compresses the fuel-air mixture, creating a rapid electric spark plug. As a result of the intense collision of the molecules, heat is generated and emits greenhouse gases that are emitted from the car exhaust.

One way to reduce emissions is to mix more air with fuel during combustion; That is, he used "dilute fuel." The idea is simple: dilute the fuel-air mixture using more air; But this is not easy to do.

Combustion engines perform best at very specific "fuel-to-air" ratios. Deviation from this ratio can quickly deactivate the engine's catalytic converter (a system designed to convert harmful gases such as nitrous oxide into safer substances). At some point, the air is so high that the engine can not ignite the fuel-air mixture at all.

"If you can work very diligently, you might get real benefits in terms of engine efficiency," says William Northrop, director of the Motor Lab at the University of Minnesota. Automakers have been trying to keep their engines running thin for a long time. "But at some point you reached the flammability zone, which is what we call the dilution zone."

The engine that can get close to the flammability range and still achieve combustion is what Aston Brook University advanced combustion expert Dimitris Asanis calls the Thermodynamic Holy Grail. Excess air in the mixture acts as a heat sink and absorbs some of the energy released during combustion. This lowers the combustion temperature, which is critical to boosting engine efficiency and reducing emissions.

But there is a problem here. "You can't light these air-diluted mixtures with ordinary spark plugs," says Dan Singleton, CEO and co-founder of Transient Plasma Systems. "They transfer energy very slowly." Excess air in the chamber cools the heat of the spark before it can dissipate enough to initiate the combustion reaction.

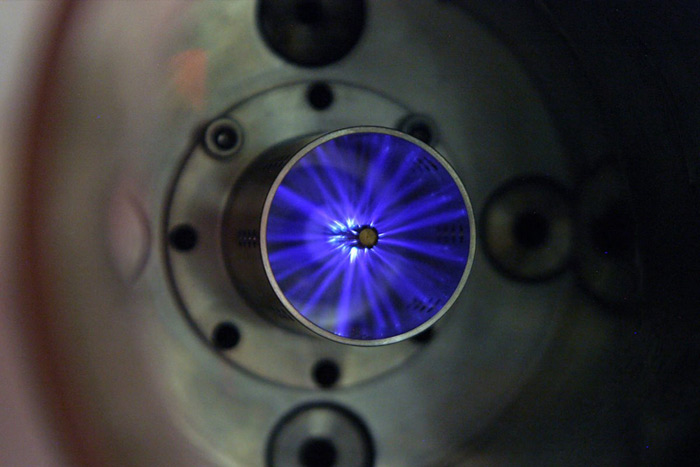

Singleton et al. Have been developing ignition systems since 2009 to solve this problem with dilute engines. This is done by ionizing the air around the candle electrodes and generating plasma pulses. To generate these plasma pulses, several megawatts of power must be provided in just a few nanoseconds. Such a power is equivalent to releasing the power of 6 trucks in a much less time than the occurrence of lightning.

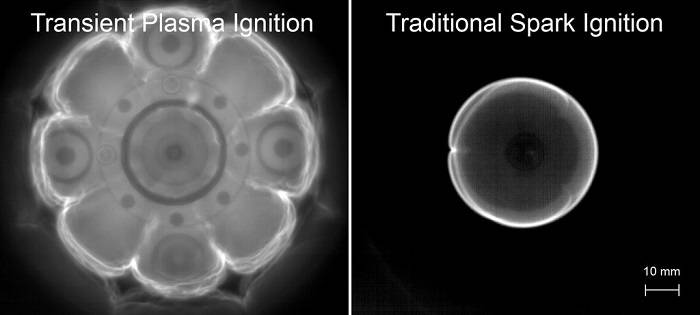

Traditional candle combustion (right) versus plasma combustion (left)

Singleton Plasma Ignition System consists of a "power" that is a bit like an Internet router. The system is connected to a set of plasma spark plugs at each cylinder head of the engine. The power receives and stores energy from the car battery and then releases it through spark plugs in the form of very rapid explosions of blue plasma. This is a lower-energy, lower-calorie version of high-energy pulsed systems such as relays and lasers that physicists use to simulate nuclear explosions.

The main difference between plasma spark plugs and conventional spark plugs is that they do not ignite the combustion reaction by transferring heat. In fact, these candles do not even have enough heat energy to light a match. Instead, plasma candles directly bombard air molecules with electrons to turn them into more reactive elements such as atomic oxygen. The rapid injection of non-thermal energy causes the molecules in the fuel mixture to collide violently, which triggers the combustion reaction. If an ordinary spark plug is like a lighter, a plasma spark plug is more like a lightning bolt. Speed is very important when it comes to dilute engines.

"The main idea of the engine is that you want everything to burn at the same time," says Jal Gandhi, who heads the Center for Engine Research at the University of Wisconsin. If you can burn the fuel just when the piston is at the top, the point of death, you will get the best possible efficiency. "This combustion event is something that is important in terms of efficiency."

The idea of using low-energy pulse power systems to achieve rapid combustion is not new. Martin Gunderson, Ph.D., a consultant to Singleton University in Southern California, has been working on these ignition systems since the early 1990s. Of course, early pulse ignition systems, which worked to reduce emissions, were expensive and large and unreliable. By the time Singleton was finishing his doctorate, the technologies needed for a cost-effective and reliable system had reached a point of maturity that seemed practical outside the lab.

A key success was the construction of high-voltage solid state switches, which were introduced in the early 2000s. Thanks to advances in switching technology, Singleton Plasma Plasma Systems can now switch several megawatts of power in a matter of nanoseconds and last hundreds of thousands of cycles. Singleton co-founded Transient Plasma Systems in 2009 with Gonderson, Andy Coty and Jason Saunders to commercialize plasma ignition.